Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

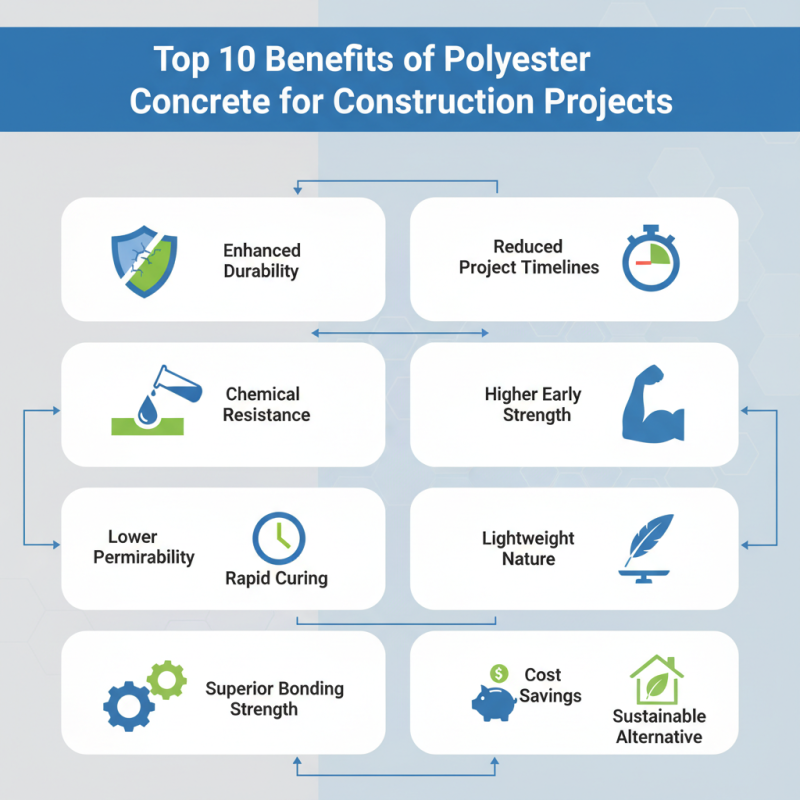

Top 10 Benefits of Polyester Concrete for Construction Projects

Polyester concrete is rapidly gaining recognition within the construction industry due to its unique properties and numerous advantages over traditional materials. According to a recent report by the American Concrete Institute, the demand for innovative concrete formulations, including polyester concrete, has surged by over 30% in the last five years alone, underscoring its importance in modern construction practices. Polyester concrete is characterized by its enhanced durability, resistance to chemicals, and lower permeability, making it an ideal choice for a wide range of applications from industrial flooring to highway repairs.

One of the key benefits of polyester concrete is its ability to cure quickly while providing superior bonding strength, significantly reducing project timelines. A study conducted by the National Institute of Standards and Technology highlighted that polyester concrete can achieve compressive strengths that are 20% higher than traditional concrete within just 24 hours, showcasing its potential to expedite construction processes. Additionally, its lightweight nature reduces structural loads, enabling more efficient design solutions that ultimately lead to cost savings in both materials and labor. This introduction to polyester concrete's benefits lays the groundwork for exploring the top ten advantages this innovative material brings to construction projects, reinforcing its role as a sustainable alternative in the building sector.

Overview of Polyester Concrete in Modern Construction

Polyester concrete is emerging as a modern solution in construction, known for its versatility and superior performance in various applications. This innovative material combines traditional aggregates with polyester resins, resulting in a composite that boasts excellent durability and resistance to environmental factors. Its rapid curing time accelerates project timelines significantly and allows for quicker turnaround in construction processes, which is ideal for both new builds and repairs.

In urban construction, where space and time are at a premium, polyester concrete stands out by providing lightweight options without compromising strength. It is particularly advantageous in scenarios where traditional concrete may be too heavy or impractical. Furthermore, its resistance to chemicals makes it a prime candidate for industrial flooring and other settings that experience harsh conditions.

As the construction industry seeks sustainable alternatives, polyester concrete also aligns with eco-friendly practices by reducing waste and enhancing longevity, making it an increasingly popular choice among modern construction projects.

Enhanced Durability of Polyester Concrete Compared to Traditional Options

Polyester concrete is gaining recognition in construction projects due to its enhanced durability compared to traditional concrete options. One of the primary benefits of polyester concrete is its resistance to chemical attacks, making it ideal for environments exposed to harsh chemicals and moisture. This attribute significantly extends the lifespan of structures, reducing maintenance costs and downtime. Furthermore, polyester concrete exhibits superior bond strength, allowing it to resist cracking and wear, which is particularly beneficial in high-traffic areas.

When considering polyester concrete for your construction projects, it is crucial to manage its application environment effectively. Ensure that the substrate is clean and free from contaminants to achieve optimal adhesion. Also, consider temperature and humidity levels at the time of application, as these factors can influence the curing process and overall performance of the concrete.

Additionally, proper mixing techniques are essential to harness the full potential of polyester concrete. Follow the manufacturer’s guidelines carefully regarding mix ratios and curing times. A well-prepared mix will enhance the concrete's strength and durability, thus maximizing its benefits over traditional concrete options. With the right approach, polyester concrete can be a powerful alternative in achieving long-lasting and resilient construction solutions.

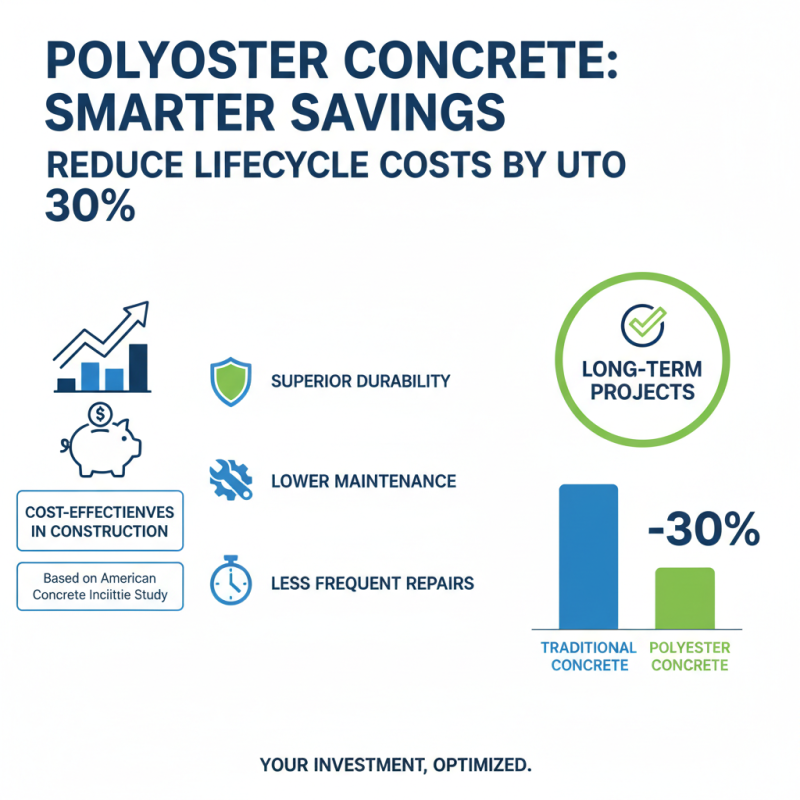

Cost-Effectiveness of Polyester Concrete in Long-Term Projects

Polyester concrete is gaining traction in the construction industry due to its impressive cost-effectiveness, especially in long-term projects. According to a study by the American Concrete Institute, polyester concrete can reduce lifecycle costs by up to 30% compared to traditional concrete materials. This reduction is primarily attributed to its superior durability and lower maintenance requirements. Projects that use polyester concrete often require less frequent repairs, leading to significant savings over time.

In addition to its durability, polyester concrete offers rapid curing times, allowing projects to progress more quickly. The National Association of Home Builders notes that quicker completion leads to earlier project turnovers, enhancing cash flow for contractors and developers. Data from industry reports indicate that implementations of polyester concrete have resulted in shortened project timelines by approximately 20% on average. This efficiency not only cuts labor costs but also minimizes the financial exposure associated with delayed project schedules, making polyester concrete a smart choice for long-term construction projects.

Sustainability and Environmental Benefits of Using Polyester Concrete

Polyester concrete is emerging as a sustainable alternative in construction, offering numerous environmental benefits that cater to modern eco-conscious projects. One significant advantage is its reduced carbon footprint compared to traditional concrete. According to a report by the American Concrete Institute, polyester concrete requires less energy to produce and often incorporates recycled materials, which can diminish the overall environmental impact of construction activities. This not only helps in conserving natural resources but also reduces waste, as polyester concrete can utilize byproducts from other industries.

Moreover, polyester concrete's durability and resistance to moisture and chemicals lead to longer lifespan structures, thereby minimizing the need for frequent repairs and replacements. A study published in the Journal of Cleaner Production indicated that constructions utilizing polyester concrete demonstrated a 30% increase in lifespan over conventional options. This durability translates to fewer resources consumed over time, aligning with sustainable building practices that aim to reduce the overall ecological footprint. Consequently, the adoption of polyester concrete is a strategic choice for projects aimed at achieving sustainability without compromising on structural integrity.

Versatility of Polyester Concrete in Various Construction Applications

Polyester concrete has emerged as a versatile solution in various construction applications, thanks to its unique properties and benefits. One notable advantage is its rapid curing time, which significantly reduces project timelines. According to the American Concrete Institute, projects utilizing polyester concrete can achieve full strength within 24 hours, compared to traditional concrete that may take days or even weeks. This quick turnaround is particularly valuable in industries like road repair and infrastructure maintenance, where minimizing downtime is crucial.

Furthermore, polyester concrete exhibits exceptional resistance to chemicals, moisture, and temperature fluctuations, making it ideal for specialized environments such as industrial flooring and marine applications. A report by the National Ready Mixed Concrete Association indicates that the durability of polyester concrete can extend its lifespan by more than 50% compared to standard concrete in harsh conditions. Additionally, its lightweight nature simplifies handling and reduces transportation costs, thereby enhancing its applicability across various construction projects, including cast-in-place applications and precast structures. The adaptability of polyester concrete positions it as a go-to material for modern construction needs, paving the way for innovative solutions that meet a wide range of engineering challenges.

Top 10 Benefits of Polyester Concrete for Construction Projects

| Benefit | Description | Application |

|---|---|---|

| Durability | Resistant to weathering, chemicals, and abrasion. | Industrial flooring, highways. |

| Fast Curing | Allows for quick installation and reduced downtime. | Pavements, repair work. |

| Lightweight | Easier to handle and transport than traditional concrete. | Precast elements, facades. |

| Aesthetic Flexibility | Can be colored or finished to meet design needs. | Architectural elements, decorative pavements. |

| Low Shrinkage | Minimizes cracking during curing. | High stress areas, overlays. |

| Enhanced Bonding | Bonds well to existing surfaces. | Repairs, resurfacing projects. |

| Environmentally Friendly | Made from recycled materials and reduces waste. | Eco-friendly construction projects. |

| Cost-Effective | Lower labor and repair costs due to longevity. | Overall construction budgets, long-term projects. |

| Versatile | Applicable in various construction contexts. | Residential, commercial, and infrastructural projects. |

| Improved Performance | Higher strength and performance compared to traditional options. | Heavy-duty applications and structural elements. |