Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

2025 Top Benefits and Applications of Polyester Concrete You Need to Know

Polyester concrete is emerging as a highly innovative and effective material within the construction industry, capturing the attention of engineers, architects, and builders alike. Its unique composition, which incorporates polyester resins in place of traditional cement, offers a wide range of benefits that make it an attractive option for various applications. As we move towards 2025, understanding the advantages of polyester concrete will be essential for those involved in construction and infrastructure development.

This article delves into the top benefits and applications of polyester concrete, highlighting its remarkable strength, durability, and resistance to environmental factors. With increased focus on sustainability and efficiency in construction practices, polyester concrete stands out as a solution that not only meets these demands but also provides enhanced performance in a variety of settings. From roadways and bridges to overlays and repairs, the versatility of polyester concrete opens new avenues for innovative construction methodologies, ensuring that it will play a crucial role in future projects.

Join us as we explore the essential features and applications of polyester concrete, equipping you with knowledge that can enhance your construction strategies and improve project outcomes in the years to come.

Overview of Polyester Concrete and Its Composition

Polyester concrete is a specialized type of concrete that incorporates polyester resins as a binder instead of the traditional Portland cement. This innovative material is gaining traction due to its unique properties and benefits tailored for various applications. The composition of polyester concrete typically includes aggregates, polyester resin, organic fillers, and catalysts. Industry reports indicate that polyester resins can enhance the overall performance of concrete by providing higher tensile strength, improved adhesion, and increased resistance to chemicals and moisture. According to a 2022 report by the American Concrete Institute, polyester concrete boasts compressive strengths exceeding 30 MPa in just a fraction of the time it takes for conventional concrete to cure.

Furthermore, the benefits of using polyester concrete are particularly evident in environments that demand durability and rapid installation. This material is particularly advantageous for constructing overlays, repair applications, and precast components. A study from the International Journal of Concrete Structures and Materials highlighted that polyester concrete can set in as little as 60 minutes, allowing for expedited project completion and minimizing downtime. Additionally, its resistance to degradation from aggressive chemicals makes it an ideal choice for industrial flooring and wastewater treatment plants. With these properties, polyester concrete stands out as a versatile solution that meets the evolving needs of the construction industry.

2025 Top Benefits and Applications of Polyester Concrete

| Benefit/Application | Description |

|---|---|

| High Durability | Polyester concrete is highly resistant to wear and chemical attacks, ensuring long-lasting structures. |

| Fast Curing Time | It cures quickly, which allows for rapid construction and less downtime in projects. |

| Excellent Bond Strength | Offers superior adhesion to existing substrates, enhancing repair applications. |

| Water Resistance | Highly resistant to moisture, making it ideal for outdoor applications. |

| Wide Range of Applications | Suitable for overlays, precast concrete, and repair of existing pavements. |

| Enhanced Aesthetic Qualities | Can be colored and textured, allowing for creative design in architectural applications. |

| Lower Weight | Lighter than conventional concrete, reducing structural load and facilitating easier handling. |

| Environmentally Friendly | Can incorporate recycled materials, contributing to sustainable construction practices. |

Key Benefits of Using Polyester Concrete in Construction

Polyester concrete has emerged as a superior alternative to traditional concrete in various construction applications due to its unique properties. One of the primary benefits is its exceptional durability. The use of polyester resin enhances the concrete's resistance to impact, chemical attack, and moisture, making it ideal for environments that may otherwise deteriorate standard concrete. This durability translates to reduced maintenance costs and longer lifespans for structures, which is a significant advantage in both commercial and residential settings.

Another key benefit of polyester concrete is its rapid curing time. This attribute allows for quicker project turnaround, minimizing downtime and enabling construction schedules to be maintained more efficiently. Additionally, polyester concrete can be tailored in terms of color and texture, providing designers with more artistic freedom and capability to meet aesthetic requirements. This versatility, coupled with its durability and speed of application, makes polyester concrete a highly attractive option for various construction projects ranging from roadways and pavements to decorative applications in landscaping and architectural features.

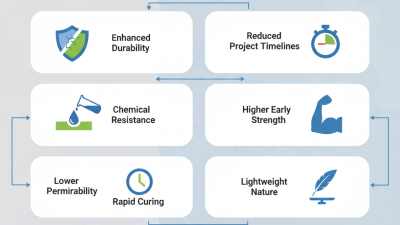

Top Benefits of Using Polyester Concrete in Construction

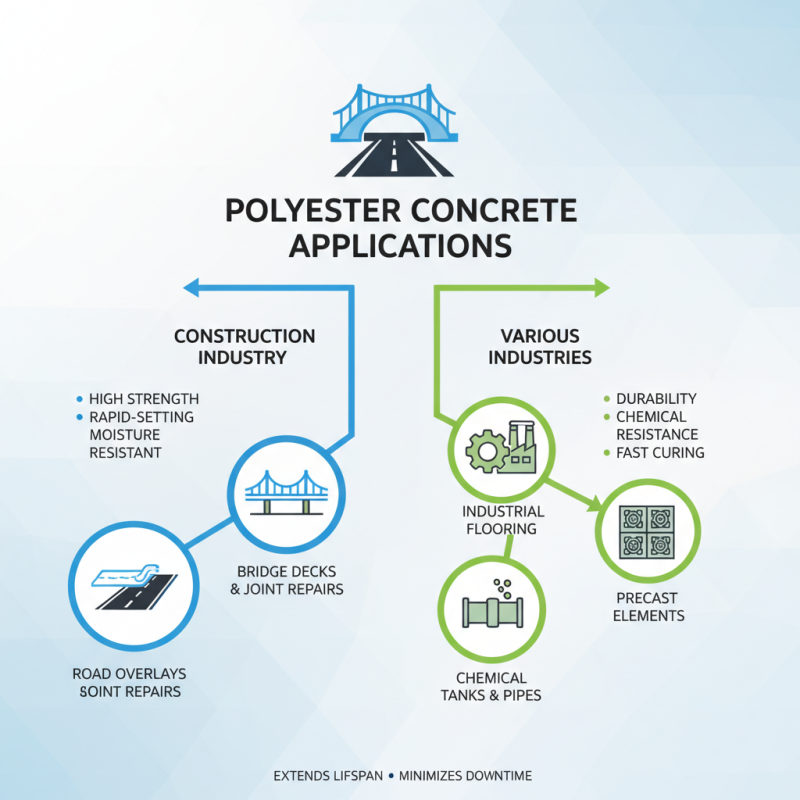

Major Applications of Polyester Concrete in Various Industries

Polyester concrete has emerged as a versatile material with a broad array of applications across various industries, thanks to its unique properties such as high strength, durability, and rapid-setting capabilities. One of the primary sectors benefiting from polyester concrete is the construction industry, where it is utilized for overlays and repairs on roads and bridges. Due to its excellent adhesion and resistance to moisture, it extends the lifespan of these structures while minimizing downtime during maintenance work. The quick curing time allows for expedited project completion, making it an attractive choice for contractors working under tight schedules.

In addition to construction, polyester concrete is gaining traction in the manufacturing sector, particularly for creating precast elements and components. Its lightweight nature and reduced shrinkage make it ideal for producing beams, panels, and other structural elements with enhanced load-bearing characteristics. Moreover, the automotive industry has started adopting polyester concrete for producing car components, including exterior cladding and panels. Its ability to resist chemicals and UV degradation ensures that these parts maintain their functionality and aesthetic appeal over time. Overall, polyester concrete's adaptability contributes to its growing presence in diverse industrial applications, showcasing its potential for innovation and efficiency.

Comparative Analysis: Polyester Concrete vs. Traditional Concrete

Polyester concrete has emerged as a compelling alternative to traditional concrete, primarily due to its superior strength, durability, and quicker curing times. In comparative analyses, research indicates that polyester concrete exhibits a compressive strength that is approximately 20-30% higher than that of traditional concrete. This enhanced strength is particularly significant in applications like roadways and pavements, where increased load-bearing capacity is essential.

Additionally, polyester concrete can achieve its specified strength in a fraction of the time, often within 24 hours, compared to several days for traditional formulations, which can drastically reduce project timelines and associated labor costs.

Moreover, the resistance to environmental factors is another key advantage. Studies show that polyester concrete has a lower permeability rate, making it less susceptible to deterioration from water infiltration and chemical attack. For instance, a report from the American Concrete Institute highlights that polyester concrete's resistance to freeze-thaw cycles and de-icing salts is considerably better than that of traditional concrete. This results in lower maintenance costs and a longer lifespan, making it a more sustainable choice in the long run. Overall, as infrastructure demands continue to evolve, the benefits and applications of polyester concrete will likely become increasingly recognized in the construction industry.

Future Trends and Innovations in Polyester Concrete Technology

The future of polyester concrete technology is set to revolutionize the construction industry with an array of innovative applications and benefits. One of the key trends is the development of advanced formulations that enhance the material's durability and sustainability. Researchers are exploring the use of recycled materials and bio-based resins to reduce environmental impact while maintaining high performance. This shift not only contributes to greener construction practices but also aligns with global initiatives aiming for more sustainable building solutions.

Moreover, the integration of smart technology into polyester concrete is gaining traction. By incorporating sensors that monitor structural integrity, the performance of polyester concrete can be optimized in real time. This innovation facilitates proactive maintenance and increases the lifespan of infrastructure projects, ultimately leading to cost savings over time. As the industry embraces these technological advancements, polyester concrete is poised to become a key player in modern construction, offering enhanced strength, versatility, and environmental benefits that meet the demands of tomorrow’s infrastructure.