Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

How to Fast Track Concrete Drying for Quick Project Completion

In the construction industry, time is often equated with money, making efficient project completion a critical focus for contractors and builders alike. One innovative approach to expedite construction timelines is through the use of techniques designed to fast track concrete drying. According to the American Concrete Institute, optimizing the curing process can significantly reduce the turnaround time for concrete projects while maintaining structural integrity and durability. Traditional concrete drying methods can take weeks, but advancements in materials and methodologies have allowed for drying times to be cut down to just a few days without compromising quality.

Fast track concrete methods not only enhance the speed of project completion but also contribute to cost savings and increased productivity. A report by the International Concrete Association reveals that projects employing rapid drying techniques can reduce overall project timelines by up to 30%, highlighting the growing importance of these solutions in meeting tight deadlines. As the demand for faster construction continues to rise in the industry, understanding and implementing effective fast track concrete drying strategies will be vital for achieving successful project outcomes and maintaining a competitive edge in the market.

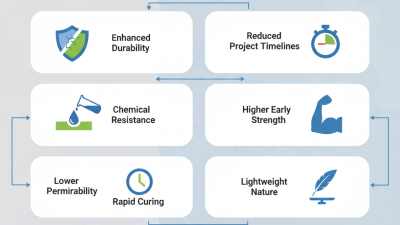

Benefits of Fast Tracking Concrete Drying for Projects

Fast tracking concrete drying offers numerous benefits for construction projects, significantly enhancing efficiency and productivity. One of the primary advantages is the reduction in project timelines. By employing techniques such as using accelerators, optimizing environmental conditions, and applying curing compounds, contractors can achieve quicker setting times. This expedites subsequent construction activities, allowing for earlier completion dates and reducing the risk of project overruns.

Another vital benefit is the improvement of overall project management. With faster drying times, teams can synchronize their schedules more effectively, leading to improved resource allocation. This flexibility provides an opportunity for contractors to take on more projects, increasing their profitability. Additionally, quicker completion can enhance customer satisfaction, as clients often prioritize timely results. As construction schedules become increasingly tight, fast tracking concrete drying is a strategic approach to meet deadlines without compromising quality.

Techniques to Enhance Concrete Drying Speed

When it comes to expediting the drying process of concrete, several techniques can enhance the overall speed and efficiency. One effective method is to employ the use of accelerators, which are chemical additives that can significantly reduce the set time of concrete. These accelerators are particularly useful in cooler weather conditions where traditional drying may take longer. By incorporating such substances, contractors can achieve a faster initial curing phase, allowing subsequent work to begin without delay.

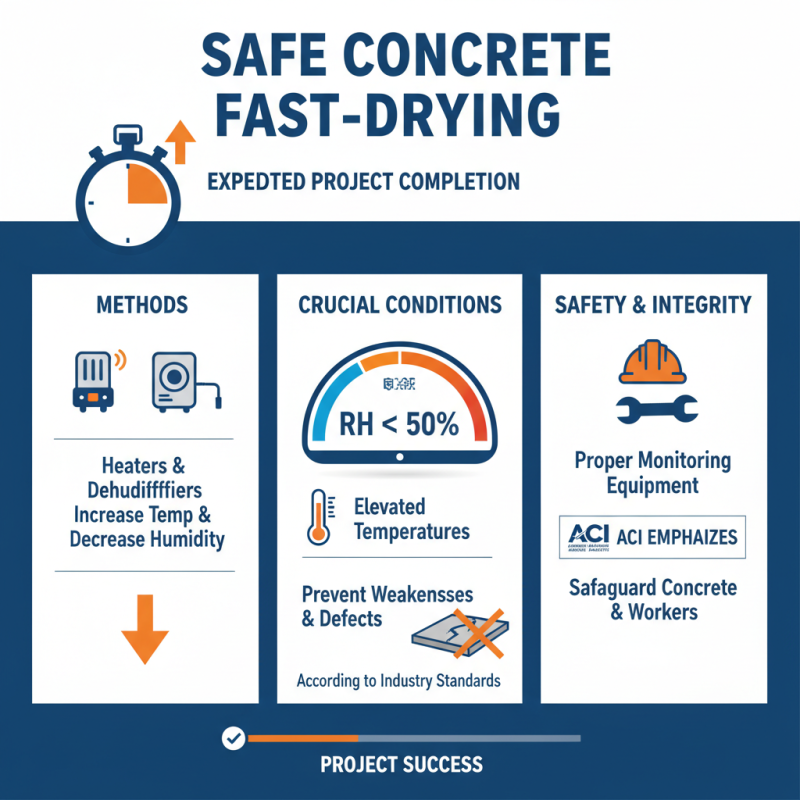

Another strategy to promote quicker concrete drying is the control of environmental conditions. Utilizing heaters or dehumidifiers in enclosed spaces can help maintain an optimal temperature and humidity level, facilitating faster evaporation of moisture from the surface. Additionally, wind and air circulation can be intentionally directed towards the curing area to aid in moisture removal. Covering the concrete with breathable materials during drying also prevents rapid evaporation, which can lead to surface cracking. By mastering these techniques, construction projects can stay on schedule while ensuring the structural integrity of the concrete.

Essential Tools and Equipment for Quick Drying

When it comes to fast-tracking concrete drying, having the right tools and equipment is essential to ensure a quick project completion. One of the primary tools to consider is a high-powered industrial fan. These fans create a continuous flow of air over the surface of the concrete, facilitating faster evaporation of moisture. Additionally, using dehumidifiers in enclosed spaces can significantly lower humidity levels, promoting quicker drying. The combination of increased airflow and reduced humidity provides an optimal environment for concrete to cure effectively and promptly.

Another crucial piece of equipment is an infrared heater. By applying mild heat directly to the concrete surface, these heaters help to accelerate the chemical curing process. It is important to use heaters with adjustable settings to prevent uneven curing or surface cracking. Furthermore, a moisture meter can be invaluable for monitoring the drying progress. By regularly checking the moisture content, contractors can assess when it is safe to proceed with the subsequent phases of the project without compromising the integrity of the concrete. Integrating these tools into the project workflow makes it possible to achieve faster drying times and maintain high quality in construction.

How to Fast Track Concrete Drying for Quick Project Completion - Essential Tools and Equipment for Quick Drying

| Tool/Equipment | Purpose | Drying Time Reduction (%) | Recommended Usage |

|---|---|---|---|

| Concrete Curing Compound | Reduces water loss and accelerates drying | 20-30% | Apply immediately after finishing |

| Heater | Increases ambient temperature to speed up curing | 15-25% | Use in cold weather conditions |

| Dehumidifier | Reduces humidity around the concrete | 10-20% | Use in enclosed spaces |

| Fans | Increases air circulation to promote evaporation | 5-15% | Position strategically for best airflow |

| High-Intensity Infrared Lamps | Direct heat application to accelerate drying | 25-35% | Use for thin slabs or limited areas |

Environmental Factors Affecting Concrete Drying Time

Environmental factors play a crucial role in determining the drying time of concrete, significantly impacting project timelines and costs. Temperature is one of the most influential factors; higher temperatures accelerate the evaporation of moisture from concrete, leading to faster drying. According to the American Concrete Institute, each 10°F increase in temperature can reduce the drying time by 25%. Conversely, lower temperatures can extend the drying process, necessitating additional time and investment in heating solutions during colder months.

Humidity is another critical aspect affecting concrete drying. High relative humidity levels can slow down the evaporation process, resulting in longer curing times. The U.S. Environmental Protection Agency reports that optimal humidity levels for concrete curing should be between 40% and 70%. When humidity exceeds these levels, it can lead to potential issues such as delayed strength gain and increased susceptibility to cracks. Monitoring environmental conditions closely will help project managers mitigate risks and optimize drying times, ensuring that projects stay on schedule without compromising the quality of the concrete work.

Safety Precautions During Accelerated Drying Processes

When fast-tracking concrete drying to ensure expedited project completion, safety precautions are paramount. Rapid drying methods, such as the use of heaters or dehumidifiers, can elevate temperatures and alter humidity levels significantly. According to industry standards, maintaining an ideal relative humidity level below 50% is crucial to prevent structural weaknesses and surface defects. The American Concrete Institute emphasizes the need for proper monitoring equipment to ensure environmental conditions remain within safe limits, thus safeguarding both the integrity of the concrete and the health of workers involved.

In addition to environmental controls, protective measures for workers become essential during accelerated drying processes. High temperatures can lead to heat stress or dehydration, particularly in confined spaces. The Occupational Safety and Health Administration (OSHA) recommends hydration breaks every hour and the provision of readily available water supplies. Furthermore, proper Personal Protective Equipment (PPE) should be mandated, including gloves and masks, to minimize exposure to dust and potential fumes from curing compounds, which, when accelerated, may emit volatile organic compounds (VOCs). By adhering to these safety considerations, projects can not only achieve accelerated timelines but also prioritize the wellbeing of those on site.