Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

How to Fast Track Concrete Curing for Optimal Results

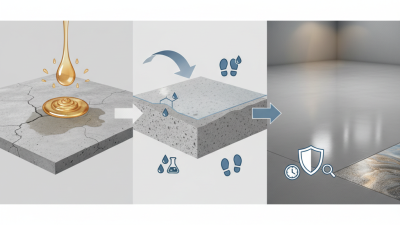

Concrete curing is a vital step in construction. When done correctly, it ensures durability and strength. However, traditional curing methods can be slow, delaying project timelines. This is where the concept of fast track concrete comes in.

Fast track concrete techniques focus on accelerating the curing process. These methods often involve using specific additives or maintaining optimal environmental conditions. Yet, achieving the right balance is not always straightforward. Improper use can lead to issues like cracking or weakened structures.

Understanding the intricacies of fast track concrete is essential. It requires careful planning and monitoring. Small miscalculations can yield unsatisfactory results. Yet, with the right approach and attention to detail, it is possible to achieve rapid curing without compromising quality. The quest for optimal results continues to drive innovation in this field.

Understanding the Importance of Concrete Curing for Durability

Concrete curing is essential for ensuring the durability of structures. It allows the concrete to develop strength and resistance to various environmental factors. When not properly cured, concrete can crack or become weak. This leads to costly repairs and safety issues down the line. Therefore, understanding the importance of concrete curing is crucial for any construction project.

Here are some tips to ensure effective curing:

Use wet coverings to keep the surface moist. This helps maintain the right temperature and humidity levels. Another option is to apply curing compounds that create a film over the concrete. Make sure to follow instructions carefully. Monitor the weather conditions, as extreme heat or cold can affect curing. If needed, adjust your curing methods accordingly.

Remember, timing is important. Curing should start immediately after finishing the concrete surface. Delaying this process can lead to irreversible damage. Pay attention to the specific needs of your mix. Different mixtures may require varied curing approaches. Contemplate your process and make adjustments where necessary. Curing is not a one-size-fits-all solution; it requires thoughtful application.

Common Methods of Concrete Curing for Faster Results

Concrete curing is essential for achieving optimal strength and durability. Multiple methods exist to accelerate the curing process. One common approach is applying water continuously. This keeps the surface moist, which aids in hydration. Using wet burlap or plastic sheets can also work well. They prevent evaporation and retain moisture.

Another effective method involves using curing compounds. These compounds form a film on the surface, which limits moisture loss. However, not all compounds work equally. Some can leave a residue that affects finishing. Always test a small area first.

Temperature control plays a significant role in curing speed. Warmer conditions can enhance hydration, but extreme heat can cause cracking. It's important to monitor the environment and adjust accordingly. Mistakes can happen. Sometimes, the curing process isn’t as efficient. Learning from these experiences can lead to better results in future projects.

Innovative Techniques to Accelerate Concrete Curing

Curing concrete properly is essential for strength and durability. Accelerating this process can lead to impressive results. One innovative technique involves using heat blankets. These can increase temperature around the concrete, promoting hydration. However, applying too much heat too quickly can cause cracking.

Another effective approach is using curing compounds. These create a film over the surface, reducing moisture loss. It’s crucial to apply them evenly. If not, some areas may dry out while others remain wet. This inconsistency can weaken the final product.

Water curing is a traditional method that remains effective. Keeping the surface moist is vital. However, it can be labor-intensive and often requires constant monitoring. Forgetting to refresh the water can lead to uneven curing. While methods may vary, the focus should always be on maintaining optimal conditions for hydration. Balancing speed and quality is the challenge.

Environmental Factors Affecting Concrete Curing Speed

Concrete curing is significantly influenced by various environmental factors. Temperature is a primary factor. Higher temperatures speed up the curing process, while low temperatures can slow it down. For instance, pouring concrete in the scorching heat of summer may seem beneficial, yet it can lead to rapid evaporation. This might cause cracking in the surface before it gains strength.

Humidity plays a critical role as well. In high humidity, the concrete retains moisture better. This aids the curing process. However, in dry conditions, much of the water used can evaporate quickly. This can result in inadequate hydration, affecting the final strength. Environmental conditions can be tricky. Too little attention to these factors can lead to disappointing outcomes.

Wind is another factor that impacts curing. Strong winds can increase evaporation rates. This may require additional curing measures to prevent damage. Having to revisit a project due to unfavorable conditions is not ideal. Concrete workers must anticipate and mitigate these effects for optimal results.

How to Fast Track Concrete Curing for Optimal Results - Environmental Factors Affecting Concrete Curing Speed

| Environmental Factor | Impact on Curing Speed | Recommended Actions |

|---|---|---|

| Temperature | Higher temperatures accelerate curing but may cause cracking. | Use curing blankets or cool water for mixing. |

| Humidity | Low humidity can increase evaporation rates. | Utilize windbreaks and misting systems. |

| Wind | Strong winds accelerate moisture loss, impacting curing. | Erect barriers to reduce wind exposure. |

| Sunlight | Direct sunlight can lead to rapid drying and surface cracking. | Cover with tarps or use curing compounds. |

| Precipitation | Excess water can hinder proper setting. | Plan to cover during inclement weather. |

Best Practices for Monitoring Curing Progress and Quality

Concrete curing is a critical process that directly affects the strength and durability of structures. Monitoring the curing progress is key to achieving optimal results. Many studies suggest that concrete can lose up to 20% of its potential strength if not cured properly. Keeping a consistent moisture level is vital. This often requires regular checks, as environmental factors can change quickly.

Using temperature monitoring tools can aid in assessing the curing environment. According to industry reports, an ideal curing temperature ranges from 50°F to 90°F. Beyond this range, the risk of cracking or incomplete curing increases significantly. Observing the temperature and humidity levels helps in making informed adjustments.

Documentation also plays a crucial role. Regularly recording environmental conditions and concrete behavior can provide insights for future projects. Some may overlook this step, leading to inconsistent results. It's essential to reflect on past curing practices to avoid repeated mistakes. Emphasizing these monitoring practices enhances quality and minimizes risks in concrete work.

Related Posts

-

2025 Top Trends in Concrete Everything You Need to Know About Concrete

-

How to Supply Concrete: Best Practices for Efficient Delivery and Placement

-

How to Fast Track Concrete Drying for Quick Project Completion

-

What is Liquid Epoxy for Concrete and How Does It Work?

-

What is Arizona Concrete? Key Facts and Benefits You Should Know

-

Top 10 Benefits of Polyester Concrete for Construction Projects