Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

2026 Best High Early Strength Concrete Applications and Benefits?

High early strength concrete is transforming the construction industry. Experts emphasize its advantages, making projects faster and more efficient. Dr. Sarah Thompson, a renowned expert in concrete technology, once stated, "High early strength concrete accelerates progress without sacrificing durability." This highlights the essential role of this material in modern builds.

Projects utilizing high early strength concrete often see significantly shorter timelines. Roads and bridges can open sooner, benefiting communities and economies. However, some contractors may rush applications, leading to potential quality concerns. This is an area needing attention.

Adjusting to the unique properties of high early strength concrete can be challenging. Proper mix designs are critical for achieving desired results. Miscalculations can undermine the benefits, presenting a risk to project integrity. Therefore, learning from past experiences is vital as the industry navigates this evolving landscape.

Overview of High Early Strength Concrete and Its Composition

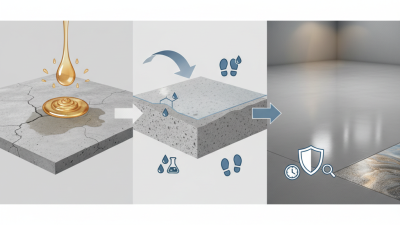

High early strength concrete (HESC) is designed to reach significant strength quickly. Its unique composition includes Portland cement, admixtures, and fine aggregates. This mix enhances hydration and promotes early setting times. According to industry reports, HESC can achieve compressive strengths of 20 MPa or more within 24 hours. This speed is crucial in construction schedules, especially in cold weather.

Despite its benefits, some challenges exist. The high cement content can lead to cracking if moisture levels are not controlled. Additionally, careful calibration of admixtures is vital to ensure consistent performance. A study by the American Concrete Institute highlighted that improper use of admixtures can result in strength loss or delayed setting. Builders sometimes overlook these details, leading to project delays.

This concrete type is optimal for rapid repair projects and precast applications. In road construction, it can minimize traffic disruptions. However, precise quality control is necessary during mixing and pouring. Miscalculations can impact long-term durability. The immediate strength gain is appealing, yet one must consider the potential for long-term issues.

Key Applications of High Early Strength Concrete in Construction Projects

High early strength concrete is increasingly used in various construction projects. Its rapid setting time offers significant advantages. For instance, it allows for quicker completion of structures. This can be crucial in urban settings where time is money. Projects like bridges and pavements benefit immensely. Their development can advance without prolonged delays.

In residential construction, high early strength concrete is preferable as well. Builders can complete foundations swiftly. This early strength means fewer interruptions due to weather. Interestingly, some projects still face challenges. Mix variations can lead to inconsistencies in strength. Not all suppliers provide reliable materials.

Furthermore, this concrete type is vital in precast applications. It enables the production of ready-to-use components. However, overseeing quality control is essential. Without careful monitoring, there can be issues with durability. Correct batching and mixing processes are crucial for success. Each project may require adjustments to achieve desired results.

Advantages of Using High Early Strength Concrete for Structural Integrity

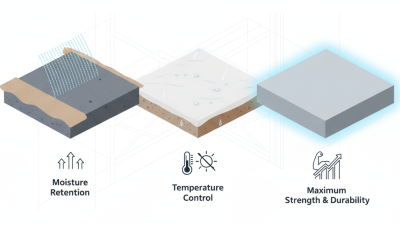

High early strength concrete is prized for its ability to gain strength quickly. This quality benefits construction projects facing tight deadlines. In urban areas, where time is money, using this type of concrete can significantly reduce the overall project duration. Workers can strip forms sooner, allowing for faster subsequent work.

The structural integrity provided by high early strength concrete is noteworthy. Its rapid strength gain reduces the risk of structural failures during critical curing periods. Projects like bridges and high-rise buildings often utilize this concrete to ensure stability under heavy loads. However, it requires careful monitoring. If the curing process is disrupted, it can lead to cracking.

While the advantages are compelling, challenges do exist. There may be a higher cost compared to regular concrete. Plus, the fast-setting nature can lead to mistakes if not managed well. Workers must be trained adequately. The focus on speed can sometimes overlook the necessary craftsmanship. Balancing speed with quality is vital.

Comparative Analysis of Cost-Effectiveness and Performance Benefits

High early strength concrete (HESC) is gaining traction in various applications due to its performance benefits. Studies indicate that HESC can achieve over 70% of its final strength within 24 hours. This characteristic drastically reduces project timelines, allowing for quicker construction turnover. For instance, in bridge rehabilitations, HESC can cut downtime by up to 30%, providing significant savings in labor costs and accelerating project completion.

Cost-effectiveness is another compelling argument for using high early strength concrete. According to a report by the American Concrete Institute, while HESC has a cost per cubic yard about 15% higher than traditional concrete, the savings realized from reduced curing time can offset this initial expense. Moreover, HESC has demonstrated superior resistance to cracking, which leads to lower maintenance costs over a structure's lifespan. However, some projects reveal that the rapid setting times can complicate placement, leading to potential waste if not managed properly.

Performance assessments show that while HESC is beneficial, its effectiveness can vary based on the mix design and application. Not all projects may achieve the anticipated results without careful planning and execution. In some cases, mismanagement during the mixing or pouring process results in compromised structural integrity. This highlights the need for skilled labor and thorough oversight in utilizing HESC to its fullest potential.

2026 Best High Early Strength Concrete Applications and Benefits

This chart compares the cost-effectiveness index and performance benefits score of various high early strength concrete applications. The data indicates that Application D provides the highest cost-effectiveness, while Application E excels in performance benefits.

Future Trends and Innovations in High Early Strength Concrete Technologies

High early strength concrete (HESC) is gaining traction in the construction industry. The innovations in HESC technologies promise faster project completions and stronger structures. In 2026, you can expect to see more effective use of additives that enhance the setting time. These advancements can reduce the dependency on traditional curing methods.

New methods for mixing and pouring are also on the horizon. Automated systems might streamline the process, improving consistency. However, these advancements come with challenges. Ensuring quality control during rapid setting is crucial. "Too fast" can lead to structural flaws. Engineers must remain vigilant during implementation.

Research is focusing on sustainable materials in HESC. Using recycled aggregates is a growing trend. Incorporating eco-friendly components can reduce environmental impacts. Yet, these options often require more testing and validation. Balancing speed and sustainability is complex, and the need for innovative thinking is vital.

Related Posts

-

What is Liquid Epoxy for Concrete and How Does It Work?

-

How to Fast Track Concrete Curing for Optimal Results

-

What is the Difference Between Cement and Concrete Explained

-

Top 10 Benefits of Epoxy Polymer Concrete for Construction

-

How to Properly Cure Hard Concrete for Maximum Strength and Durability

-

What is Batching of Concrete and Why is it Important?