Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

Top 10 Benefits of Epoxy Polymer Concrete for Construction

Epoxy polymer concrete has transformed the construction industry significantly. According to Dr. Emily Carter, a leading expert in polymer materials, “Epoxy polymer concrete combines strength with versatility.” This material has become a favorite among builders for its durability and resistance to extreme conditions.

Epoxy polymer concrete is ideal for various applications. It effectively resists chemicals and moisture, making it suitable for industrial floors and outdoor structures. However, some builders struggle with the application process. Mistakes in mixing ratios can lead to performance issues. It is crucial to follow guidelines closely to avoid these problems.

The benefits of epoxy polymer concrete are plentiful, yet the challenges remain. Ensuring a proper cure time is essential; otherwise, the bond may weaken. It is important to acknowledge that while this material is advantageous, improper use can lead to costly repairs. Builders need to weigh these factors carefully as they incorporate epoxy polymer concrete into their projects.

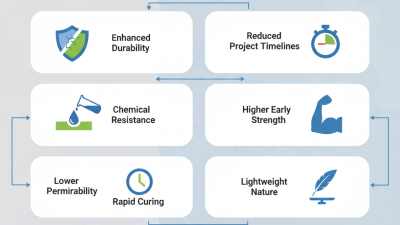

Benefits of Epoxy Polymer Concrete: Enhanced Durability in Construction

Epoxy polymer concrete is gaining attention in construction for its enhanced durability. Unlike traditional concrete, it possesses remarkable resistance to wear and chemical damage. This makes it ideal for industrial floors and areas subjected to heavy machinery. The surfaces remain intact even under severe conditions, reducing maintenance efforts.

Moreover, epoxy polymer concrete simplifies the installation process. It can be applied quickly, allowing for faster project completion. However, careful surface preparation is essential for optimal adhesion. Neglecting this step can lead to premature failure. Observing these details is crucial, as mistakes can be costly.

Another attractive feature is its versatility. Epoxy polymer concrete can be tailored for various applications. From decorative finishes to functional elements, it meets diverse needs. Yet, keeping in mind the potential for cracks under heavy stress is important. Over time, any material can show wear, and this one is no exception. Regular assessments ensure longevity.

Top 10 Benefits of Epoxy Polymer Concrete for Construction

| Benefit | Description |

|---|---|

| Enhanced Durability | Epoxy polymer concrete offers superior resistance to wear, abrasion, and chemical attacks, leading to longer-lasting surfaces. |

| Fast Curing Time | The quick curing properties allow for faster project completion, reducing downtime on construction sites. |

| Versatility | This material can be used in a variety of applications, from industrial floors to decorative surfaces. |

| Low Maintenance | Once cured, epoxy polymer concrete requires minimal maintenance compared to traditional concrete. |

| Resistance to Moisture | This concrete type is impermeable to moisture, which helps prevent water damage and prolongs lifespan. |

| Chemical Resistance | It withstands various chemicals, making it ideal for laboratories and manufacturing facilities. |

| Aesthetic Flexibility | Available in various colors and finishes, allowing for creative and attractive designs. |

| Improved Adhesion | Strong adhesion properties make it suitable for bonding with existing surfaces. |

| Eco-Friendliness | Many epoxy systems are low in VOCs, contributing to a healthier environment. |

| Cost-Effectiveness | While initial costs may be higher, the durability and low maintenance lead to long-term savings. |

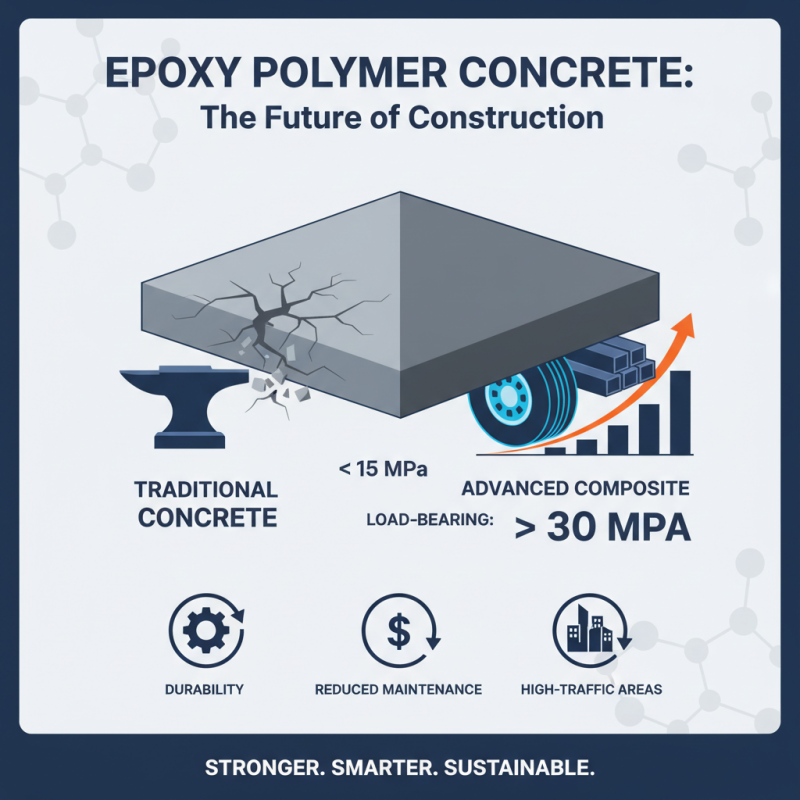

Superior Load-Bearing Capacity of Epoxy Polymer Concrete Solutions

Epoxy polymer concrete is revolutionizing the construction industry with its exceptional load-bearing capacity. Unlike traditional concrete, this advanced material can withstand heavy loads without cracking or losing integrity. Research shows that epoxy polymer concrete can handle loads exceeding 30 MPa, making it ideal for high-traffic areas like industrial floors and commercial spaces. This impressive strength ensures long-lasting structures and minimizes maintenance costs.

In many situations, the flexibility of epoxy polymer concrete allows for innovative designs. Builders can create thinner slabs while maintaining strength, optimizing material usage. However, the application process can be challenging and requires skilled labor. Poor mixing ratios can lead to reduced performance, highlighting the importance of proper techniques. Companies often overlook this step, which can affect the overall project.

The durability of epoxy polymer concrete means it lasts much longer, even in harsh environments. It resists chemicals, moisture, and temperature fluctuations. A report from the Journal of Applied Polymer Science indicates that structures using epoxy polymer concrete have a lifespan that can exceed 50 years. Yet, constant advancements in materials underline the need for ongoing education in this field. Being aware of new developments is crucial for maximizing the benefits of this exceptional material.

Chemical Resistance of Epoxy Polymer Concrete in Harsh Environments

Epoxy polymer concrete stands out in construction due to its impressive chemical resistance. This feature is vital in harsh environments, such as industrial facilities and chemical plants. A study from the Journal of Materials in Civil Engineering noted that epoxy polymer concrete can withstand corrosive substances like sulfuric acid and hydrochloric acid. This means fewer repairs are necessary.

In addition to its durability, epoxy polymer concrete maintains its integrity under extreme conditions. Research indicates that it can endure significant temperature fluctuations without degrading. However, there are challenges. Proper application is crucial; if not done correctly, the material may not perform as expected. Some professionals have reported issues related to bonding with other materials, which can lead to failures.

Moreover, the environmental impact of the chemicals used in production must be considered. While epoxy provides strength, its components can pose challenges. There is a growing need for more sustainable alternatives. Construction professionals must stay informed about innovations in this area, balancing performance and environmental responsibility. The right approach can lead to long-lasting and robust solutions.

Cost-Effectiveness: Long-Term Financial Benefits of Epoxy Polymer Concrete

Epoxy polymer concrete offers significant cost-effectiveness for construction projects. According to industry reports, this material can reduce maintenance costs by up to 30% over its lifespan. While the initial investment might seem high, the longevity of epoxy polymer concrete makes it a wise choice. It can last two to three times longer than traditional concrete, leading to fewer replacements and repairs.

Additionally, epoxy polymer concrete is highly resistant to chemicals. This resistance minimizes damage and eliminates the need for costly repairs. A report from the Construction Materials Association indicates that structures using epoxy can save an average of 15% annually on maintenance. This figure shows just how financially beneficial the right material choice can be.

Despite these advantages, some may find the installation process challenging. The curing time and necessary environmental conditions can impact project schedules. Construction teams need to be well-prepared to ensure optimal results. Balancing initial costs with long-term savings is crucial, but the potential return on investment can be substantial if managed effectively.

Top 10 Benefits of Epoxy Polymer Concrete for Construction

This chart illustrates the top 10 benefits of using epoxy polymer concrete in construction. Each benefit is scored out of 10 based on its importance and effectiveness in enhancing construction projects, showcasing the long-term financial advantages associated with utilizing this material.

Rapid Curing Times: Accelerated Project Timelines with Epoxy Polymer Concrete

Epoxy polymer concrete offers rapid curing times that significantly speed up project timelines. This advantage can transform how construction teams approach their work. Traditionally, concrete requires days to cure. In contrast, epoxy polymer concrete can cure within hours, allowing for quicker project turnarounds. This means fewer delays and increased productivity on job sites.

Implementing this material, however, isn't without challenges. The fast curing process can put pressure on workers to achieve perfect application. Mistakes made in haste can lead to future issues. It might require a highly skilled workforce that understands the nuances of this material. The reward is worth the risk, but caution is necessary.

Additionally, weather conditions can affect the curing process. Extreme heat or humidity may require adjustments to techniques. Awareness of these factors is crucial for successful application. Despite these considerations, the benefits of reduced project timelines are undeniable. Epoxy polymer concrete can push projects forward in competitive markets. The potential for innovation and efficiency is immense.

Related Posts

-

How to Fast Track Concrete Drying for Quick Project Completion

-

2025 Top Trends in Concrete Everything You Need to Know About Concrete

-

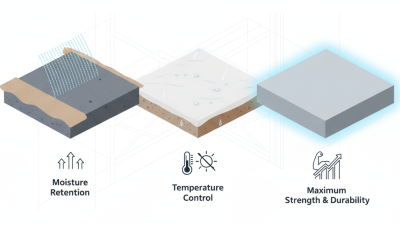

How to Properly Cure Hard Concrete for Maximum Strength and Durability

-

How to Fast Track Concrete Curing for Optimal Results

-

How to Supply Concrete: Best Practices for Efficient Delivery and Placement

-

Top 10 Benefits of Polyester Concrete for Construction Projects