Mon - Fri 8:00AM - 5:00PM Central

1150 SE Hamblen Rd, Lee's Summit, MO 64081

What is Batching of Concrete and Why is it Important?

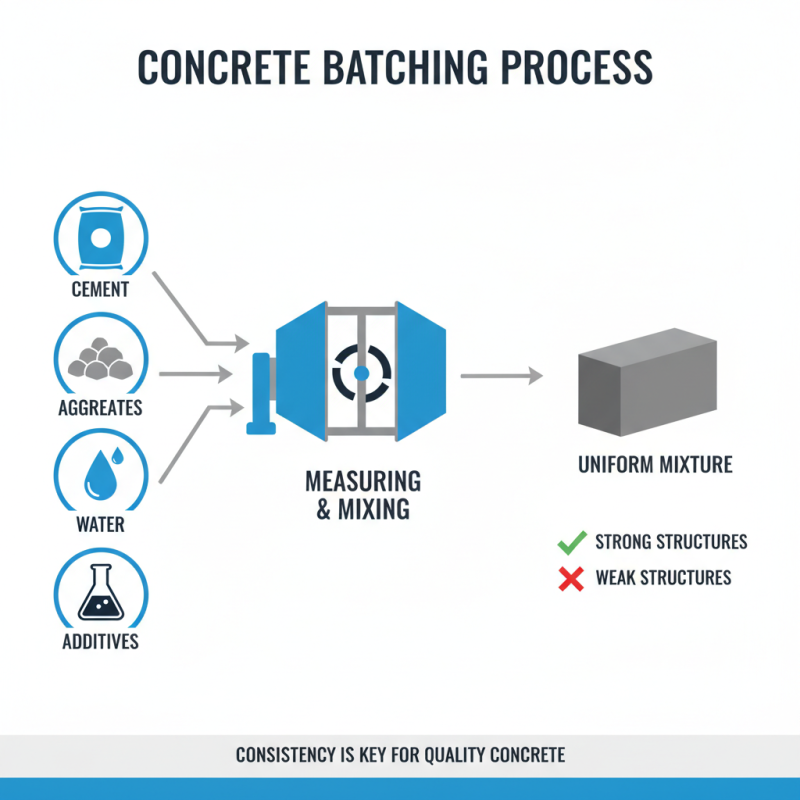

The batching of concrete plays a critical role in construction. It refers to measuring and mixing concrete ingredients in precise proportions. This process ensures that the final product meets structural requirements. Without proper batching, the quality can suffer.

Errors in batching can lead to weak or unstable concrete. For instance, too much water can weaken the mix. On the other hand, too little water can make it unworkable. These imbalances often lead to costly repairs and delays. Accurate batching is essential for durability and strength.

Many contractors overlook this process, thinking it's straightforward. However, even minor mistakes can have major consequences. Understanding the importance of batching of concrete is vital. It directly affects the longevity of structures. Investing time in proper batching can save future headaches.

Definition and Overview of Concrete Batching

Concrete batching is the process of measuring and mixing ingredients to create concrete. This includes cement, aggregates, water, and additives. The goal is to produce a uniform mixture that meets specific project requirements. Consistency is key. Variations in the mix can lead to weak structures.

Tips: Always use clean, high-quality materials. Impurities can affect the final product. Measure ingredients accurately to maintain the desired properties. Mix them evenly to prevent weak points in the concrete.

Understanding how batching works is crucial for construction quality. Inaccurate measurements can lead to issues like cracks or inadequate strength. Familiarize yourself with the equipment and techniques used in batching. It's an area where small mistakes can have significant consequences. Experiment with different ratios to find the optimal mix for your project.

Tips: Keep a detailed log of your batching process. Review it regularly to identify patterns and areas for improvement. Collaboration with experienced team members can provide valuable insights, helping you refine your methods over time.

Importance of Accurate Batching in Construction Projects

Accurate batching of concrete is crucial in construction projects. It ensures that the right proportions of materials are mixed. Incorrect batching can lead to weak structures and increased costs. For example, too much water can weaken concrete strength. On the other hand, too little water can complicate the mixing process.

In construction, precision matters. A small error in measuring aggregates can result in a mix that does not meet specifications. This can delay projects and push budgets over the limit. Workers might struggle with inconsistent concrete, leading to wasted material and time. It’s essential to perform regular checks and double-verify measurements.

However, achieving perfect batching isn't easy. Human error can slip in despite best efforts. A distracted worker might misread a scale. Equipment might malfunction, affecting the accuracy of measurements. Reflecting on these imperfections can lead to improvements in processes. Constant vigilance and training are needed to minimize these issues.

Concrete Batching Importance in Construction Projects

Methods of Concrete Batching: Manual vs. Automated

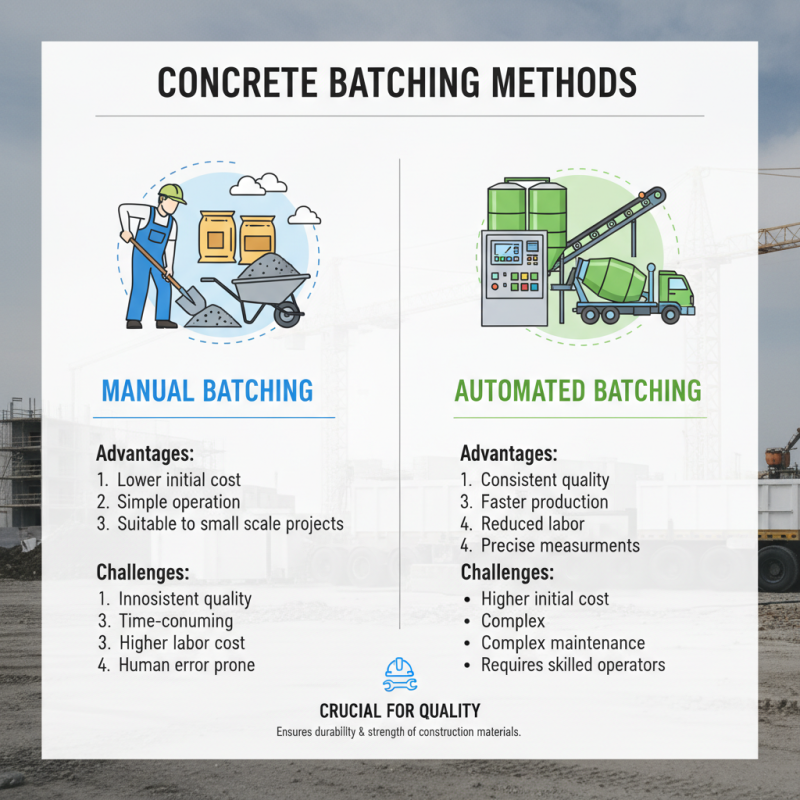

Concrete batching is crucial for ensuring the quality of construction materials. There are two primary methods: manual batching and automated batching. Each method has its own advantages and challenges.

Manual batching relies on skilled workers to measure and mix materials. While this method allows for flexibility, it can lead to inconsistencies. A report from the National Ready Mixed Concrete Association indicates that manual errors can result in a 5-10% variance in concrete quality. Workers must be precise. Any small mistake affects the final product.

On the other hand, automated batching utilizes advanced technology. Machines weigh and mix the ingredients accurately. Automation reduces human error and improves efficiency. According to industry statistics, automated systems can increase batching speed by up to 30%. However, initial setup costs can be high, and training is necessary. Some small companies may struggle to adopt this technology fully. Balancing accuracy and cost is a continuous challenge for many in the industry.

Factors Influencing Concrete Batching Process

The concrete batching process is crucial for ensuring the quality of a concrete mix. Several factors can influence this process. One key element is the accuracy of the measurements. An imprecise measure of materials can lead to weak concrete. If the ratio of cement to water is off, the final product may not meet structural standards.

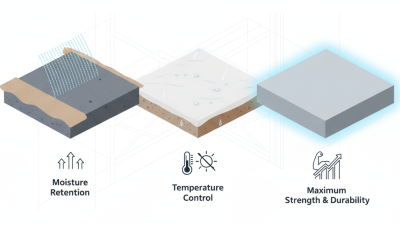

Environmental conditions also play a role. Temperature and humidity can affect the curing of concrete. In hot weather, for instance, the water may evaporate too quickly. This can lead to cracks and surface issues. Cold weather can slow down the curing process, making it harder to reach desired strength.

Moreover, the skill level of the personnel involved is vital. Inexperienced workers might misinterpret the batching procedure. This can lead to inconsistent mixes and quality issues. Regular training and oversight can help mitigate these problems. Analyzing past batches could provide insights for improvements, ensuring better outcomes in future projects.

Common Challenges and Solutions in Concrete Batching

Concrete batching is a critical process in construction. However, several challenges can arise during this phase. Ensuring proper measurement of materials is vital. A small error can lead to significant inconsistencies. One common problem is moisture content in aggregates. It can affect the water-to-cement ratio. This introduces variability in strength and durability.

To combat these issues, regular testing should be standard practice. Testing aggregates for moisture helps in making accurate adjustments. Keeping detailed logs helps track changes and improves accuracy over time. Automated batching systems are also beneficial. They decrease the chance of human error.

Tips: Always verify the calibration of your equipment. Consider implementing a quality control checklist. This helps in addressing small inconsistencies before they escalate. Reflect on past batching experiences. These lessons can improve future projects and prevent mistakes.

What is Batching of Concrete and Why is it Important? - Common Challenges and Solutions in Concrete Batching

| Dimension | Description | Importance | Common Challenges | Solutions |

|---|---|---|---|---|

| Measurement Accuracy | Ensuring precise amounts of materials are used | Critical for achieving desired strength and durability | Human error in measurements | Use automated batching systems |

| Material Quality | Consistency in raw material quality | Affects overall performance of concrete | Variability in supply | Regular testing and quality checks |

| Mix Design | Proportion of ingredients in the concrete mix | Ensures desired properties like strength and workability | Difficulty in achieving the right mix | Use of software for mix design optimization |

| Batching Time | Total time taken to batch materials | Impact on project timelines | Delays caused by equipment malfunction | Regular maintenance of batching equipment |

| Environmental Factors | Impact of weather conditions on batching | Ensures optimal curing conditions | Extreme weather can affect material properties | Monitor weather and adjust batching procedures accordingly |

Related Posts

-

What is the Difference Between Cement and Concrete Explained

-

How to Fast Track Concrete Curing for Optimal Results

-

Top 10 Benefits of Epoxy Polymer Concrete for Construction

-

How to Properly Cure Hard Concrete for Maximum Strength and Durability

-

How to Supply Concrete: Best Practices for Efficient Delivery and Placement

-

2025 Top Trends in Concrete Everything You Need to Know About Concrete